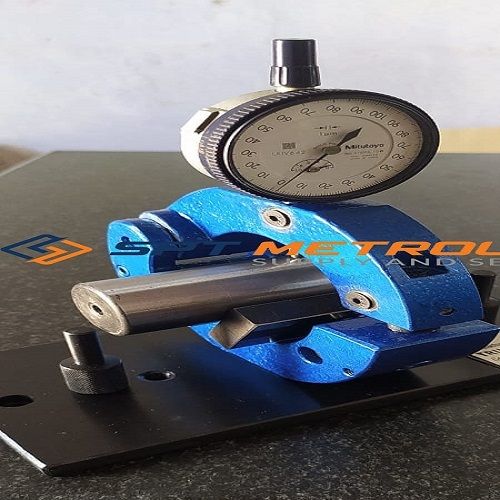

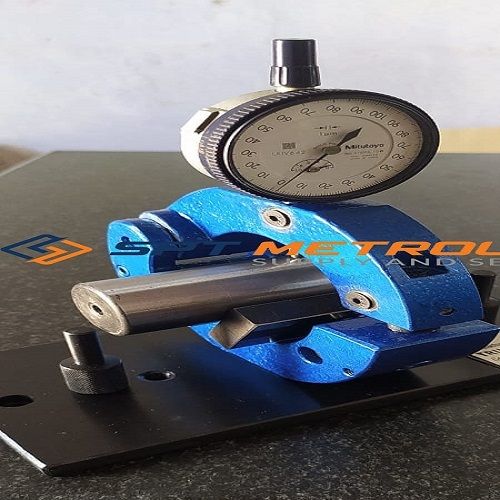

Take advantage of the new release OD, Run out, and Taper Checking Gauge and elevate your measurement precision. This top-drawer bench-top gauge is perfect for measurement of OD, run-out, and taper for shafts and cylindrical parts. With a renowned premium dial indicator offering stellar accuracy (0.015 mm) and a sharp resolution of 0.01 mm, it accommodates up to 250 mm OD. Stably held by a V Block & Roller system, its matte and chrome finish resists corrosion. Access unmatched quality-portable, highly reliable, and supplied with calibration certificate. Ideal for tool rooms, inspection, or production in India, this gauge brings trusted performance within your reach.

Versatile Application for Precision Measurement

The OD, Run out, and Taper checking gauge excels on various application surfaces, including alloy and stainless shafts, precision ground components, and cylindrical parts. Its reliable design is tailored for use in tool rooms, production floors, and inspection areas. The portable configuration and easy setup make it suitable for a range of use types, supporting mechanics, machinists, and QC inspectors in comprehensive measurement and quality control tasks beyond just one material or process.

Robust Supply Ability and Domestic Market Support

With strong supply ability, this OD, Run out, and Taper checking gauge is available for prompt delivery across India. Sample policy options ensure you make informed purchasing decisions, with transparent pricing reflecting the list price and additional packaging charges. The gauge is carefully packaged for safe transit. Servicing the main domestic market, including dealers, traders, and manufacturers, we guarantee availability and support for every distributor, supplier, and retailer in your network.

FAQ's of OD ,Run out , Taper checking gauge:

Q: How is the OD, Run out, and Taper checking gauge calibrated before use?

A: Each gauge is supplied with a calibration certificate, ensuring that it meets the specified accuracy and performance standards before shipment. Calibration is done using reference standards for high reliability.

Q: What surfaces and parts can this gauge be used on?

A: This gauge is suitable for measuring outer diameter, run-out, and taper on a wide range of cylindrical parts, including shafts and precision components made from stainless steel, alloy steel, and other metals.

Q: Where can the gauge be commonly used in India?

A: It is widely utilized in tool rooms, inspection labs, production environments, and manufacturing plants-anywhere precision measurement is required for quality control.

Q: What is the process of setting up the gauge for accurate measurements?

A: Setting up the gauge is easy and portable. Secure the workpiece on the V Block & Roller for stable support, align it according to the indicator, and begin measurement. The setup ensures repeatable and vibration-free readings.

Q: What are the benefits of a manual, silent operation gauge?

A: The manual, mute operation ensures noise-free workshops and eliminates the need for electrical power, making the gauge cost-efficient and adaptable to various environments.